HP and Torque Comparison on Centrifugally Supercharged Engine with Elbows on the Supercharger Inlet

Installation of the 489" supercharged FE involved adapting the shaker hood scoop assembly to work with the supercharger. This was done by fabricating a custom air cleaner that ducted air from the hood scoop out to the side of the air cleaner, through two 4" diameter 90 degree cast aluminum elbows, and into the supercharger inlet. This allowed the supercharged engine to be packaged neatly under the hood of the 1969 Mach 1, but running the supercharger's air inlet through the 90 degree elbows was questionable from a performance standpoint. So, this setup was tested on the dyno.

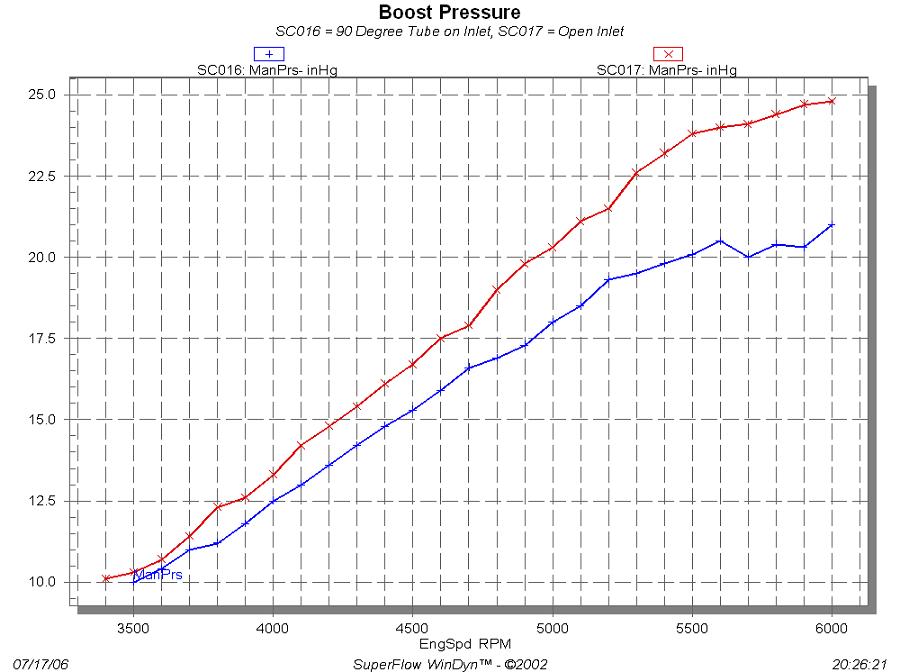

The top chart at right shows the intake manifold pressure developed with the engine running with only one of the 90 degree elbows on the supercharger inlet, and with the inlet open. Clearly, the elbow limited the boost that the supercharger could develop.

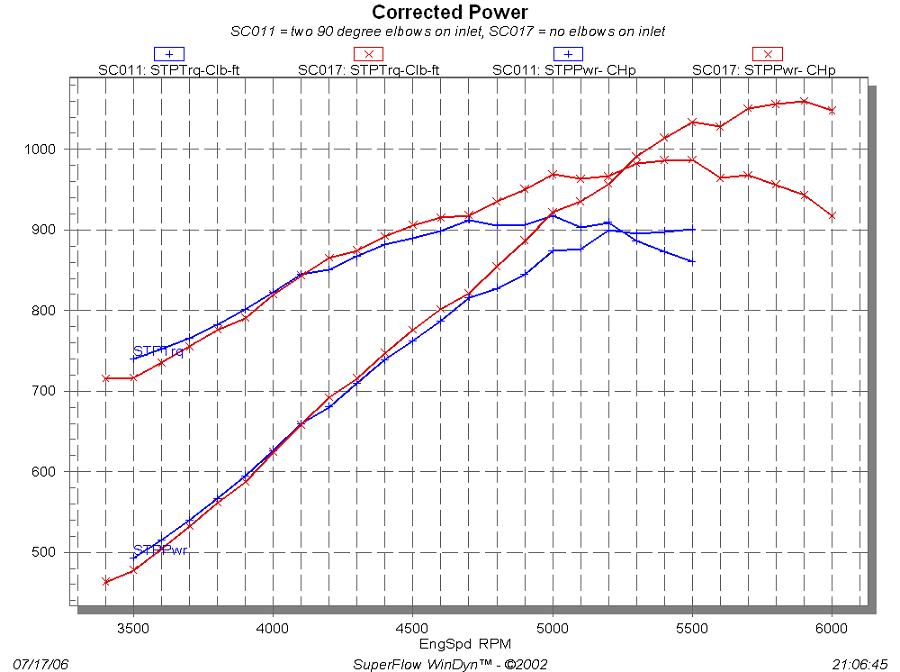

The bottom chart shows a comparison of torque and horsepower with the elbows installed, and not installed. The elbows cost about 150 horsepower, forcing a revision to the installation that allowed the supercharger to draw air from a hole in the inner fender, rather than through the two 90 degree elbows.